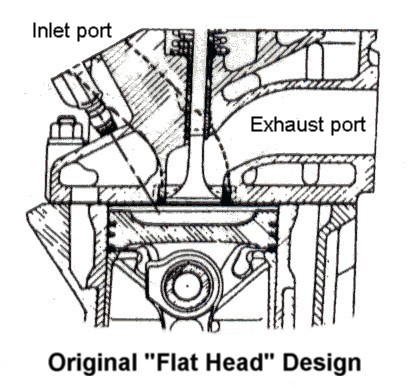

| XJ-S and Saloon - 5.3 and 6 litre. V12 Types. There are essentially 2 variants of the Jaguar V12 engine with respect to the cylinder head/combustion chamber design. In its original form, produced from 1971 to 1981, the inlet and exhaust valves were situated alongside each other and the cylinder heads formed a flat top to a combustion chamber in the form of a bowl in the piston crown (diagram 1). Apart from when the piston is at the top of the bore the valves are completely unobstructed and provide excellent flow capability. For that reason most high power and racing V12s are based on this early "flat head" engine. The drawback of the arrangement is poor part throttle efficiency which forced Jaguar to investigate ways of drastically improving the highway cruise fuel consumption.

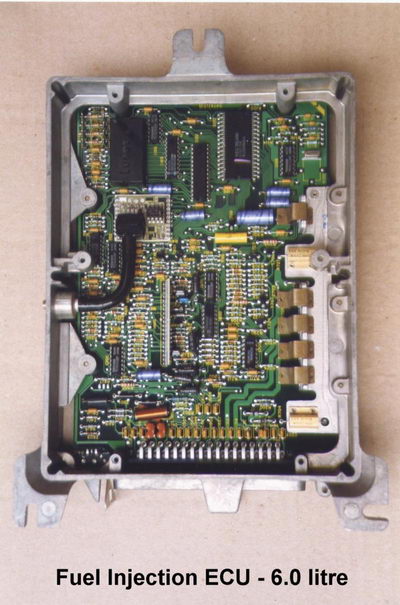

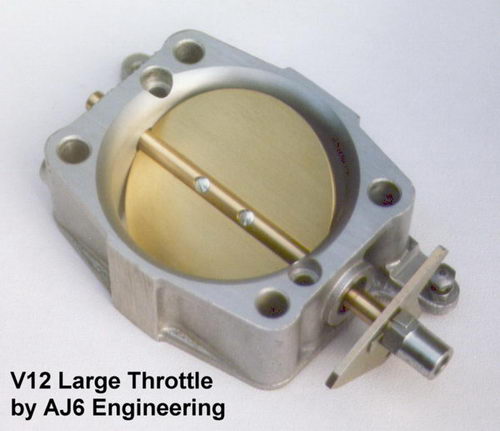

This resulted in the so-called HE V12 which entered production in 1981 and applied to all production V12s after that time. The new arrangement has the exhaust valve recessed deeply into the cylinder head to form a compact oval chamber with the spark plug located at one end. As the flat topped piston approaches the top of the bore it forces much of the charge into a shallow channel around the inlet valve from where it squirts tangentially to generate a high speed vortex in the chamber (diagram 2 & 3). This creates ideal conditions in which to burn relatively weak mixtures at high compression ratios, thereby achieving the required cruise fuel efficiency. Although the power output of the production HE V12 is on a par with the best of the flat head engines the potential for significant further power increases is compromised by the pocketed exhaust valve. It is hard to squeeze more than about 400 b.h.p. out of an HE V12. European flat head V12s had 9:1 compression ratio and US emission versions had 7.8:1 but the star was the 10:1 compression version made for just one year from mid-1980. HE V12s were normally 12.5:1 compression or 11.5:1 for emission versions and all Marelli 5.3 engines. The 6 litre ran at 11:1 compression. For those who are interested there are some typical V12 power and torque curves in the 'V12 Archives' section. Performance Upgrades. We have identified 4 key areas in which performance and driver satisfaction can be markedly improved at relatively modest cost. Most of these conversions are applicable to any V12 with electronic fuel injection. 1: The HE V12 engine in particular is compromised by the need to achieve the most favourable steady state economy figures. The practical result is that in everyday urban traffic situations the driver often finds the transmission part-throttle downshifting, thereby using more fuel, to achieve a reasonable level of performance. We have found that improving the response from the engine in part throttle operation will often deliver the same performance in a higher gear, thus the overall fuel consumption is hardly altered even though the engine is much livelier. We found that quite minor changes to the basic fuel program can achieve this effect but even better results can be obtained by also magnifying the response to throttle movement. This makes the engine feel like the thoroughbred that it should be and is the purpose of our SUPER ENHANCED ECU. Surprisingly, improving the engine response in this way also profoundly changes the way the transmission responds when the car is driven with more enthusiasm. The more pronounced change of vacuum signal to the transmission seems to have the effect of noticeably sharpening up the shift pattern and in combination with the improved engine response, the 3 speed auto transmission becomes much easier to live with.  The Super Enhanced ECU is not available for the earlier (1975-80) V12s using Bosch/Lucas D Jetronic injection although we do provide modified ECUs for when those engines are to be fitted with our other performance conversions. 2: The factory induction system is fundamentally well designed as one might expect but the intakes are deliberately small as a means of limiting intake noise. It is a simple matter to enlarge the intakes to 3" or so diameter but many people would then find the intake noise to be excessive if not downright unpleasant (particularly on ABS cars with the forward mounted filter boxes). Our solution is to enlarge the standard intakes slightly and add a supplementary intake to each air filter housing drawing air from below. Then we replace the original paper air filters with specially made low loss foam filters (washable, not throw-away) and we bore out the throttles from 2.5" to 2.875" diameter for which we make new butterfly discs with the correct closing angle geometry and machine a radiused entry instead of the original sharp edge.  This completes the primary aim of getting more air into the engine with good equality of flow to the individual cylinders. Allied to a Super Enhanced ECU this all constitutes our SUPER ENHANCED LARGE THROTTLE KIT producing around 25 b.h.p. extra on a standard V12. The Large Throttle kit is also available for the 1975-80 V12 for which a modified ECU is supplied. This is the best selling V12 performance conversion of all time - we have sold many hundreds since introducing it in 1986.

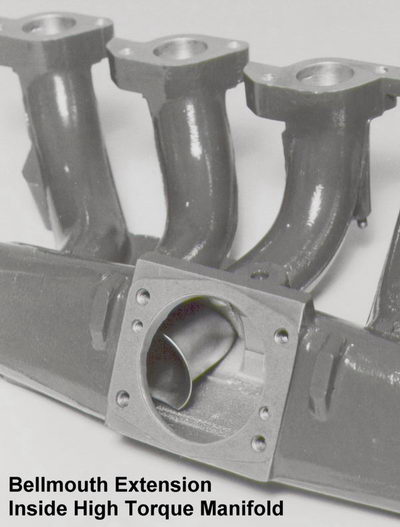

The Large Throttle kit will actually pass enough air to produce around 450 b.h.p. from a fully developed racing engine using modified production based inlet manifolds but the same throttles on our Ram Plenum manifolds (see V12 Archives) proved good enough for nearly 600 b.h.p. on the appropriate engine. However people with more modest ambitions will find that the Large Throttle kit works well enough on a standard engine to cheer the car up noticeably without ruining its Jaguar qualities. Another way round the noise problem is to arrange ducting through the inner wing to collect air from behind the headlights - so called "cool air ducts" - but whilst cool air is certainly good for power, it is bad for cruise economy. The rule about air temperature is simple, cool for power (maximum charge density), hot for economy (minimum charge density to reduce losses due to throttling). In this respect the standard arrangement is much better than many people think. Sure, the under-bonnet air temperature at idle can easily get up around 70 C but the faster the car goes the lower the air temperature falls - simply because the radiator is passing its heat to a much larger quantity of air per second - so at 80 m.p.h. the engine is breathing air at around 45 C. That's still a bit higher than the ideal but not nearly so bad as many people think. Obviously the arrangement helps to maximise economy in moderate speed urban cruise without compromising top end power too much. From a power point of view it is just as important to increase the restricted intake area as to concentrate on air temperature alone, but the noise level must remain acceptable. Jaguar's solution on the 6 litre XJ-S was to take the intakes over the top of the radiator but despite small "tuning holes" in the ducts to kill resonance, to some people those engines display an unpleasant low speed drone. 3: We found that the torque, or mid-range power, of the engine could be noticeably improved by subtle changes to the individual passages in the inlet manifolds leading to each cylinder. Jaguar designed their V12 inlet manifolds originally in the 1960s when manufacturing techniques were such that pragmatism often took precedence over idealism. Certainly the importance of things like ram length and tract bellmouths was well enough known but Walter Hassan's design team had no choice but to compromise for space and budget reasons. The basic design has remained the same ever since, only changing in detail for the different engine specifications over the years. Nevertheless it is instructive that when the combined brains of Cosworth and Ford's RVT group recently created the much vaunted V12 for Aston Martin they equipped it with inlet manifolds of identical layout, but in modernised form.

Taking the manifolds closer to the ideal is not just a simple matter of making the passages bigger - it is about optimising the length and entry profile into each of the tracts to better exploit induced harmonic resonances in the air as it flows towards the cylinder. Any tube containing air can be made to resonate at certain critical frequencies in the manner of an organ pipe. Such is the case with the inlet tracts of an engine and if the natural resonance frequencies can be matched to the engine speed then a mild supercharging effect can be induced. Get it wrong and the reverse will apply, resulting in a loss of performance. Our own experiments suggested that the individual tracts were shorter than the ideal for a wide torque band so we concluded that considerable improvement would be possible if we extended them by adding bell-mouthed ram pipes inside the manifold.  These are added after cutting the manifold open and then it is carefully welded back together and finished to look just like the standard item. An extra option is to have the grooved manifold tops of earlier cars reworked to be exactly like the face-lifted 92 MY cars with framed "Jaguar V12" badges.

Adding these manifolds to our Large Throttle Conversion and Super Enhanced ECU constitutes our PLUS TORQUE CONVERSION which provides clear benefits over almost the whole speed range. Whilst very effective on the 5.3 V12 the gains on the 6.0 V12 are better still. A short ram pipe version is available for racing with more emphasis on top end power (see racing notes at end). One of our customers reported the following acceleration time gains from fitting the Plus Torque Conversion to a 1994 6 litre XJ-S.

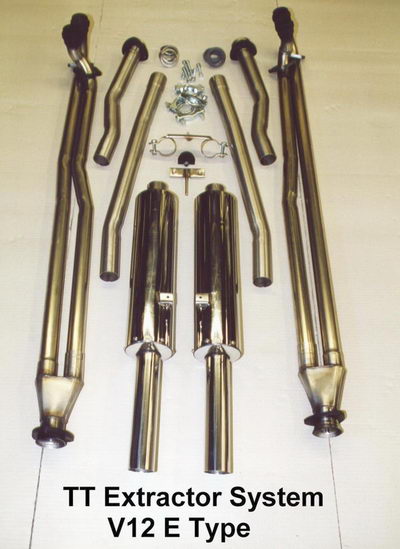

| Standard | Plus Torque | | 0-60 | 6.6 | 5.3 | | 0-100; | 16 | 12.8 | | 50-70 | 6 | 5 | | 60-80 | 4 | 3 | 4. The design of the exhaust system is dominated by considerations such as refinement and, of course, emissions legislation. Many people think that the exhaust system on a modern Jaguar is a little too quiet for a car with high performance pretensions and it is quite possible to obtain a reasonable increase in performance allied to a pleasing exhaust note without becoming an antisocial monster. The simplest way of doing this is to replace the first silencer boxes below the rear seats with our SILENCER SUBSTITUTE PIPES for a gain of 15-20 b.h.p. The noise level is not excessive and they can be used on most cars with or without catalysts. Our LARGE BORE EXHAUST SYSTEM with all straight-through silencers removes virtually all the restriction from the system but in reality only gives about 5-10 b.h.p. more than the Silencer Substitute Pipes so is only really worth thinking about if the complete system is in need of renewal. Our TT EXTRACTOR system is a tuned front section designed specifically to boost mid-range torque (which is what most people find useful). The original Y pipes below the standard manifolds (headers) are replaced by pairs of pipes of tuned length and diameter which merge just behind the transmission then feed through short adapters onto a pair of Silencer Substitute Pipes. From that point on the original system can be retained, renewed as a complete TT EXTRACTOR system, or replaced by a Large Bore Rear system for extra top end power but this option does tend to be noisier than some people would like for road use. The TT system significantly outperforms a Large Bore system so much so that fueling changes (included in the kit) are essential for it to work properly. The adapter pipes can be supplied with lambda sensor tappings but heated sensors must be used because of the distance from the engine. A wiring extension kit is included and we can supply heated lambda sensors as an extra. A version of the TT EXTRACTOR system is also available for the V12 E Type but this is only available as a complete system because the centre silencer can no longer be used. Special rear boxes had to be developed to achieve an appropriate blend of performance and noise suppression.

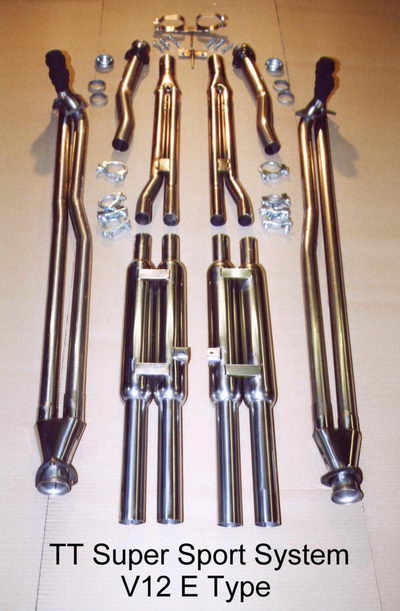

V12 E Types with the standard carburettors do not need any fueling changes as they tend to be self regulating but those cars that have been converted to fuel injection require similar changes (included) to other EFI V12s. Finally there is our new TT SUPER SPORT system for the V12 E Type - the ultimate system for road or track. Those who like to hear their V12 on full song will love it, but it is definitely not for the fainthearted.

RACING OPTIONS. Most of our road car performance conversions are available in slightly different forms for racing. Because intake noise is not a problem on a race car we can supply the air filter assemblies for the Large Throttle Kit with 3" diameter bell-mouth intakes on the front, the Racing High Torque inlet manifolds have shorter internal bell-mouths, and the Racing TT Exhaust has shorter pipe lengths before the merge point and should be used in combination with a large bore rear section. In each case the effectiveness is pushed higher up the speed range where it is more useful on the track. Revised ECU mapping can be supplied where necessary. An Adjustable ECU is often useful for racing so that the fueling can be easily altered as different modifications are added or refined. |

0 comments:

Post a Comment